This can be erratic and sometimes be confused with a “dead pedal” complaint that can be caused by a sticky advance piston, which usually sets a P0216 code. MAP sensor can go bad and not set a code, check reading with scan tool versus actual. Low or no fuel supply pressure, restricted fuel filter(s). PERFORMANCE BOXES Performance boxes that tap into, or connect into, vehicle wiring should be removed to make certain that they are not causing any of the following complaints.īuy 24 Valve 5.9 Injectors LOW POWER: 1. NOTE: The following information is not a substitute for the proper diagnostic manuals, but to share some of the common problems we have run across. This filter should be changed at the same interval as the other fuel filter(s). If the vehicle is equipped with an aftermarket supply pump system, be aware that there may be an inline fuel filter in the fuel supply line prior to the supply pump. In order to maintain good fuel flow, especially with performance modifications, you may need to add an aftermarket supply pump. Continued driving, when the fuel is under a vacuum, can cause cavitation, which will damage the injection pump. When the supply pump in the injection pump is pulling more fuel than the supply pump in the tank is pushing, then pressure becomes a vacuum because volume isn’t high enough. Some vehicles with the updated in-tank supply pump won’t maintain a positive pressure during a test drive. The problem with their volume test with an unrestricted flow is their specifications for volume aren’t high enough. According to Chrysler, pressure doesn’t matter, only volume.

4psi at the inlet to the injection pump with a clean fuel filter allows for a pressure drop across the fuel filter when it is dirty. Failure to maintain a pressurized flow of un-aerated fuel will cause injection pump damage. The supply pump should maintain at least 4psi at the inlet to t he injection pump on a W.O.T.

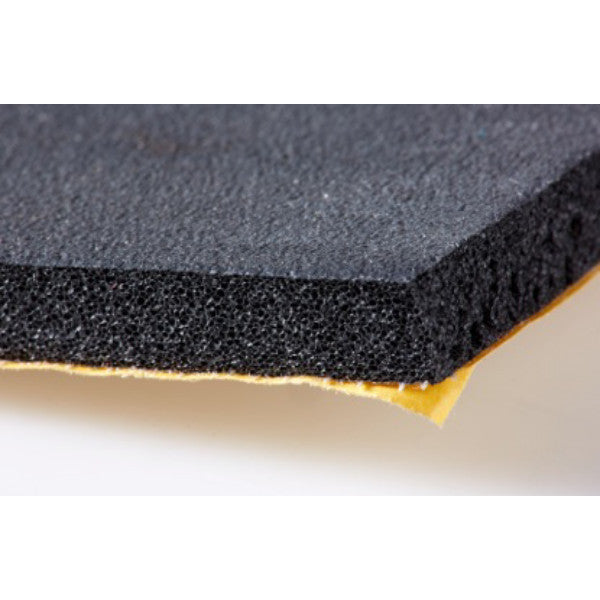

#BD NOISE ISOLATOR FOR P0216 CODE#

There are cases where a P0216 code (pump timing failure – advance operation) will be stored in the ECM in conjunction with the complaint which makes diagnostics somewhat easier, but it is still important to do thorough diagnostics.įUEL SUPPLY PUMP PRESSURE: The supply pump is critical for the longevity of the VP44 injection pum p. In order to properly diagnose this complaint all of the other possibilities must be eliminated because there are often no codes stored in the ECM in conjunction with the complaint.

#BD NOISE ISOLATOR FOR P0216 FREE#

Another cause could be from faulty lead free soldered connections that fail over time in the pump PSG. This causes the advance piston to stick in the advance housing bore due to cavitation damage. The problem will most likely be an internal VP44 fault caused by low or no fuel supply pump pressure. The others are as follows: faulty throttle position sensor (APPS), defective MAP sensor (not sending a boost signal to the ECM for reference), a defective aftermarket performance box that ties in with the MAP and/or APPS sensor, OR least commonly a faulty ECM. There a few causes for this complaint but the vast majority are internal VP44 failures. In our experience it is often when the engine is cold, and the customer complains of losing throttle response when pulling out into traffic. The complaint may also be described as “loss of throttle”, “no throttle response”, or “intermittent low power”, “engine only idles” or “poor throttle response”. Being more descriptive about the specific complaint will improve diagnostics. Inspect the serpentine system at 60K miles and replace worn components by 90K miles or as advised by the manufacturer.DEAD PEDAL: This is the most common of all complaints on the 1998.5-2002 Dodge Cummins with the Bosch VP44 injection pump. The best way to prevent belt failure is to Be System Smart and think I60 & R90. A squealing belt can be a sign that the belt tensioner is failing and causing belt misalignment. While the belt is off for replacement, give the belt tensioner pulley a spin and listen for bearing noises. A Gates belt wear gauge is included with the purchase of this belt. If you see these, it is time to replace the belt. You should check the serpentine belt at every oil change for cracks and chunks missing out of it and general wear. Meets or exceeds SAE J1459 specifications.Reinforced with stretch-resistant, thermally active polyester tensile members.Special formation process for precise dimensional control.Precision ground to assure optimum belt-to-pulley fit.Last 50%-60% longer than value line belts.Special belt constructions eliminate belt noise, reduce tension loss and solve problem drive applications.

The Gates Micro-V K080816 serpentine belt for your '89-'91 Dodge Cummins Turbo Diesel truck is designed to be the quietest and highest performing belts in the industry.

0 kommentar(er)

0 kommentar(er)